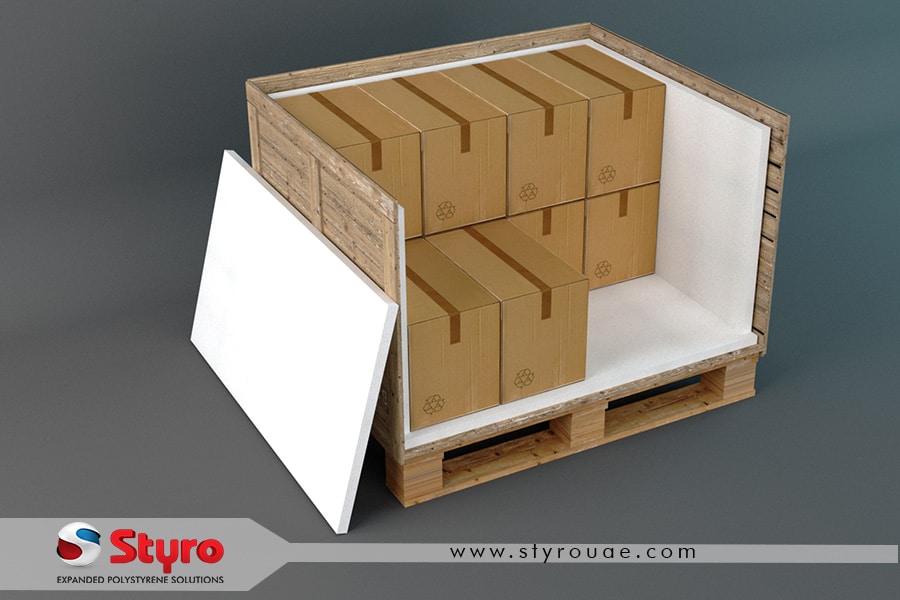

Polystyrene sheets Dubai, commonly known as foam boards, are lightweight and rigid panels used in various industries and applications. Understanding what polystyrene sheets are made of can provide insight into their unique properties and uses. Polystyrene sheets are typically composed of expanded polystyrene (EPS) or extruded polystyrene (XPS) foam. Let’s delve into the details of these materials.

Expanded polystyrene (EPS):

Expanded polystyrene (EPS) is a lightweight and versatile material commonly used in the production of polystyrene sheets. It is made from polystyrene beads that are expanded and molded into shape. The manufacturing process involves the following steps:

Pre-expansion:

Polystyrene beads are heated with steam to expand them and create a cellular structure.

Fusion:

The expanded beads are then fused together using heat and pressure to form solid blocks or sheets.

Cutting:

The solid blocks or sheets are cut into desired sizes and shapes to create EPS polystyrene sheets.

EPS polystyrene sheets have a closed-cell structure, which provides excellent thermal insulation, moisture resistance, and durability. They are lightweight, making them easy to handle and transport.

Extruded polystyrene (XPS):

Extruded polystyrene (XPS) is another common material used in the production of polystyrene sheets. Unlike EPS, XPS is manufactured through an extrusion process. The manufacturing process involves the following steps:

Mixing:

Polystyrene resin is mixed with blowing agents and additives to create a homogeneous mixture.

Extrusion:

The mixture is then extruded through a die, where it expands and forms a continuous sheet with a closed-cell structure.

Cooling and cutting:

The extruded sheet is cooled and then cut into desired sizes and shapes to create XPS polystyrene sheets.

XPS polystyrene sheets have a uniform and dense cellular structure, providing enhanced strength, moisture resistance, and thermal insulation properties. They are rigid and have a smooth surface, making them suitable for various applications.

Both EPS and XPS polystyrene sheets offer excellent insulation, impact resistance, and versatility. They are widely used in the construction industry for insulation, concrete formwork, and architectural modeling. They are also utilized in packaging, arts and crafts, signage, and DIY projects.

It’s important to note that while polystyrene sheets offer many benefits, proper handling and disposal are essential due to their environmental impact. Recycling programs are available in some areas to mitigate the environmental concerns associated with polystyrene waste.

RELATED ARTICLES

Recent News

- How To Store Cat Food Properly

- 5 Benefits Of Professional Disinfection Services

- 4 Key Services Offered By Hospitality Consultants

- Maintaining Oral Hygiene With Crowned Teeth

- How A Signboard Maker Can Alter Your Business

- The Steps To Take After You’ve Been Injured

- The Importance Of A Structured Property Payment Plan

- How To Protect Sensitive Documents In Storage Units

- How To Create Shareable Content On Social Media

- How To Choose Materials For Re- Usable Stands